- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

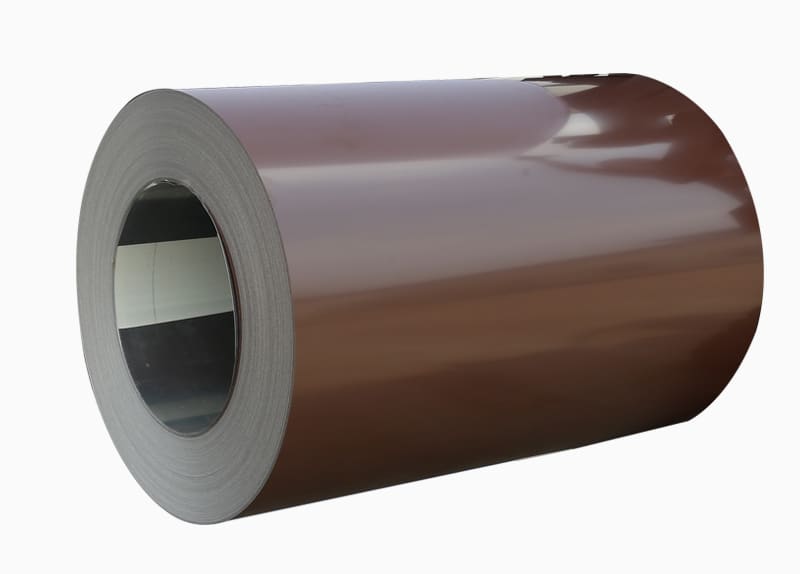

When it comes to choosing materials for construction and manufacturing, PPGI and PPGL steel coils often emerge as top contenders. Both offer excellent durability and versatility, but each has unique characteristics that make it suitable for specific applications. This article compares PPGI and PPGL steel coils to help you make an informed decision.

Composition

PPGI:

PPGI steel coils are made by coating galvanized steel with a layer of paint. The galvanized base consists of a zinc coating that offers corrosion resistance.

PPGL:

PPGL steel coils are produced by coating galvalume steel, which is a mix of zinc, aluminum, and silicon. This composition provides superior resistance to corrosion and thermal stability compared to galvanized steel.

Corrosion Resistance

While both PPGI and PPGL steel coils are designed to resist corrosion, PPGL has the edge due to its galvalume base. The aluminum in the galvalume layer forms a protective barrier that enhances the material’s ability to withstand harsh environments.

Thermal Stability

PPGL steel coils outperform PPGI in terms of thermal stability. They can endure higher temperatures without compromising their structural integrity, making them ideal for applications in hot climates or industrial settings.

Aesthetic Options

Both PPGI and PPGL steel coils offer a wide range of colors and finishes. However, PPGI is often preferred for projects where vibrant and glossy finishes are required. PPGL, on the other hand, is more commonly used for subtle and matte finishes.

Cost

PPGI steel coils are generally more cost-effective than PPGL, making them a popular choice for budget-conscious projects. However, the slightly higher cost of PPGL is justified by its enhanced performance in challenging environments.

Applications

PPGI:

Ideal for interior applications, appliances, and projects where cost and aesthetics are primary considerations.

PPGL:

Suitable for exterior applications, industrial settings, and environments with high exposure to heat and moisture.

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...