- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

The production of color steel sheets involves a series of sophisticated processes designed to ensure high-quality products. Understanding these processes not only sheds light on the technology behind color steel sheets but also highlights their advantages over traditional materials.

Step 1: Steel Coil Preparation

The manufacturing process begins with the selection of high-quality steel coils. These coils are typically made from hot-rolled or cold-rolled steel, depending on the desired specifications. The steel coils undergo surface treatment, which includes cleaning and degreasing to remove any impurities, ensuring a smooth surface for painting.

Step 2: Galvanization

After preparation, the steel coils are galvanized through either hot-dip or electro-galvanizing methods. In hot-dip galvanizing, the steel is immersed in molten zinc, creating a protective layer that prevents corrosion. Electro-galvanizing involves applying zinc through an electrochemical process. Both methods provide excellent corrosion resistance, making color steel sheets suitable for various applications.

Step 3: Coating Application

Once galvanized, the steel sheets are ready for the application of paint. This is typically done through a continuous coil coating process, where the steel coils are fed through a series of rollers. The paint is applied in a controlled manner, ensuring an even layer. The coating can consist of a primer and topcoat, often made from polyester, polyurethane, or acrylic, depending on the desired finish and durability.

Step 4: Curing

After the paint application, the coated sheets are subjected to a curing process in a drying oven. This step is crucial as it allows the paint to bond firmly with the metal surface, enhancing durability and resistance to scratches, chemicals, and weathering. Proper curing is essential for achieving a long-lasting finish.

Step 5: Inspection and Quality Control

Once the sheets are coated and cured, they undergo rigorous quality control inspections. Manufacturers check for color consistency, coating thickness, adhesion, and surface defects. This step ensures that only high-quality products reach the market, minimizing returns and enhancing customer satisfaction.

Step 6: Cutting and Packaging

After passing quality control, the color steel sheets are cut to specified sizes according to customer requirements. They are then packaged carefully to prevent damage during transportation, ensuring that they arrive at their destination in perfect condition.

With high anti-rust performance, they are popular used in co...

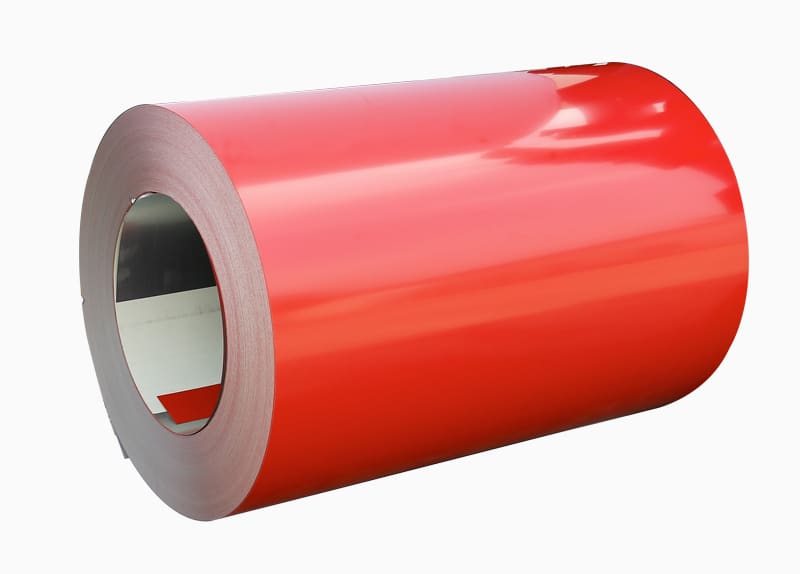

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...